Quality Trailer Axles in Melbourne

Transtyle Rubber Torsion Axles

When it comes to buying trailer axles in Melbourne, Transtyle own rubber torsion axle provides a significant improvement to ride quality in comparison to the conventional spring axles because both sides of the axle operate independently from each another. The rubber elastomer springs also help to smooth out the ride by absorbing at lot of the bumps, hence it is also a quieter ride. Maintenances free and no lea spring to get rust.

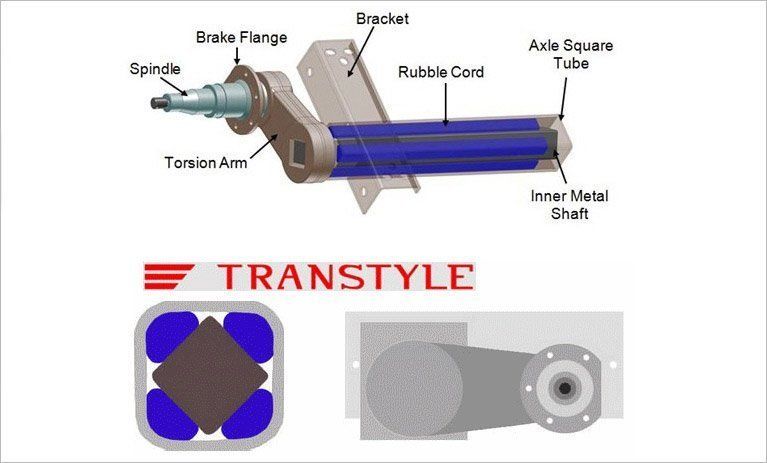

HOW DOES RUBBER TORSION SYSTEM WORK

Four natural rubber cords within the main structure of the axle beam surround the steel torsion bar. The wheel/hub spindle is attached to a lever, called the torsion arm assembly. This assembly comprises of the torsion arm, torsion bar and spindle. When load is applied to the trailer, the torsion arm assembly pivots around the torsion bar, causing a rolling or compressive resistance in the rubber cords inside the axle beam.

The Transtyle rubber torsion axle offers a significant improvement to ride quality in comparison to the conventional spring axles because both sides of the axle operate independently from each another. The rubber elastomer springs also help to smooth out the ride by absorbing at lot of the bumps, hence it is also a quieter ride.

CLICK HERETO DOWNLOAD RUBBER TORSION AXLE CATALOGUE

Grease Exchange System

All of our axles will come with Grease Exchange system , this system is the best to protect your wheel bearing from corrosion , wear, and water entry ,

With the Transtyle Grease Exchange System, grease is pumped through the hub via the grease zerk located at the end of the grease cap. Grease is pushed through the bearings and out of the exit hole at the rear of the spindle. Ensure that the seal plug has been removed to allow the grease for flow through.

Old grease that was inside the hub is forced out and exits through the rear hole of the spindle. Continue to pump new grease through the system until you are able to see a steady flow of new grease coming from the exit at the rear of the spindle – this ensures that all of the old grease has been flushed out. Once lubrication is complete, replace the seal plug.

With the Transtyle Grease Exchange System, grease is pumped through the hub via the grease zerk located at the end of the grease cap. Grease is pushed through the bearings and out of the exit hole at the rear of the spindle. Ensure that the seal plug has been removed to allow the grease for flow through.

Old grease that was inside the hub is forced out and exits through the rear hole of the spindle. Continue to pump new grease through the system until you are able to see a steady flow of new grease coming from the exit at the rear of the spindle – this ensures that all of the old grease has been flushed out. Once lubrication is complete, replace the seal plug.

General Information

Transtyle axles currently manufacture four series of the axle ,

Series #1 - **Coming Soon**

Series #2 - With three size capacity 1250kg - 1,500kg and 1,700kg

Series #3 - With three size capacity 2000kg - 2,200kg and 2,500kg

Series #4 - With two size capacity 2,750kg and 3,000kg

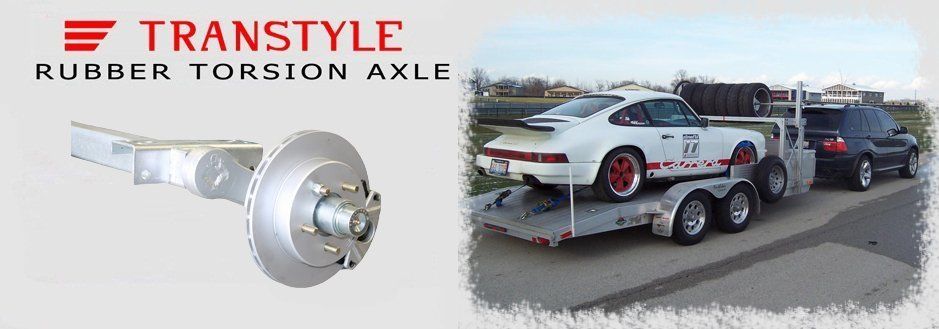

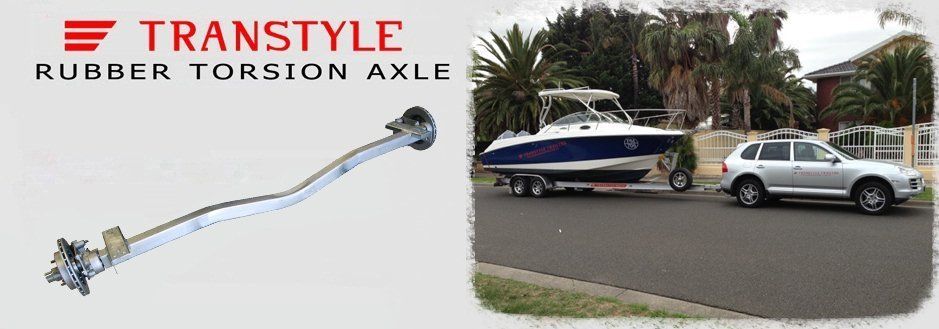

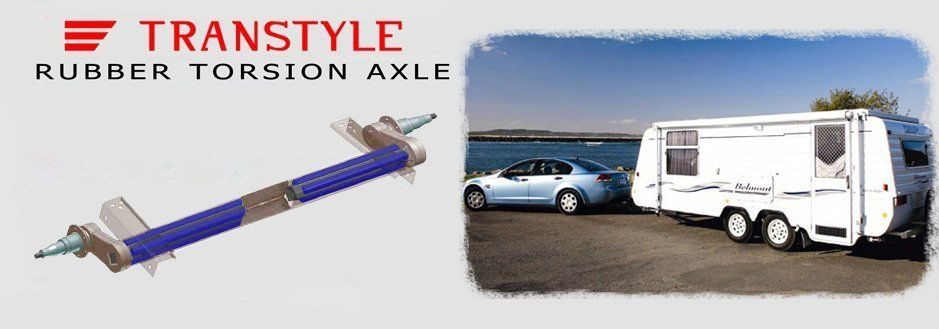

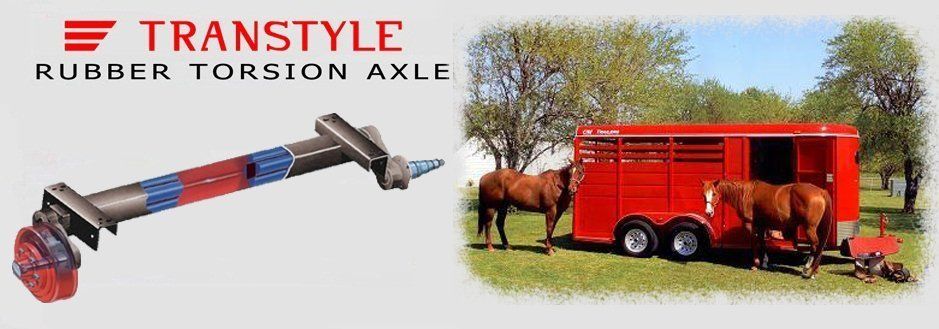

Transtyle rubber torsion axles are suitable for all types of trailers - boat trailers, car trailers, caravans, horse floats etc. They are available as Half Axles (2pc unit) that will suit any chassis width, or a Full Beams Axle. The full beam axle is available as a Straight axle or a V Shape axle.

The axle beams are Hot dip Galvanised and the torsion arm and inner metal shaft are finish with Dacromet plating for protection against corrosion.

Capacity Allowance

When using for tandem axle trailers, you must allow for a 20% decrease in axle capacity.

Example = two axles rated at 2,500kg is suitable for a 4,000kg ATM tandem trailer

When using for tri axle trailers, you must allow for a 25% decrease in axle capacity.

Example = three axles rated at 2,000kg is suitable for a 4,500kg ATM tri axle trailer

Example = two axles rated at 2,500kg is suitable for a 4,000kg ATM tandem trailer

When using for tri axle trailers, you must allow for a 25% decrease in axle capacity.

Example = three axles rated at 2,000kg is suitable for a 4,500kg ATM tri axle trailer

MUDGUARD CLEARANCE

When assembling the axles to the trailer, you must keep a minimum clearance of 100mm from the top of the tyre to the guard.

CLICK HERE

FOR OUR SPARE PARTS CATALOGUE

CLICK HERE

TO DOWNLOAD OUR TORSION AXLE ORDER FORM